Until 2020, the only logistical data available to the National Malaria Control Program was the national paper-based reporting system, which reports stock-on-hand and consumption data from SDPs to the district and regional levels before being available at the national level. But paper-based reporting was characterized by incomplete data reported and insufficient reporting rates and a lack of quality control systems, which prevented a regular flow of data for timely decision-making.

The paper-based logistics management information system needed to allow for receiving complete stock data quickly enough to plan monthly distribution cycles. GHSC-PSM identified the call center as a solution with the capacity to quickly and regularly collect stock data from all health centers to calculate their monthly consumption in order to inform the quantities to be delivered each month. (Simultaneously, GHSC-PSM is providing support to strengthen the current paper-based LMIS and the upcoming electronic LMIS, as the call center aims to complement not replace a functioning LMIS.) The call center is being used to inform the last-mile distribution model.

GHSC-PSM previously implemented the call center model in South Sudan to increase stock data visibility and availability for malaria, family planning and reproductive health commodities. Haiti, Mali, and Burkina Faso are also successfully using call centers.

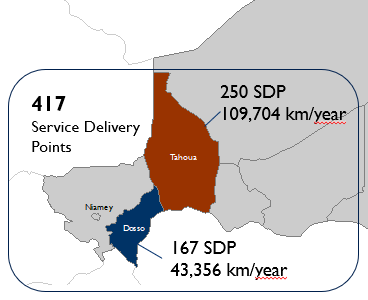

In March 2020, GHSC-PSM started piloting the call center to collect stock data from 417 sites in Dosso and Tahoua and, in January 2021, the last mile distribution pilot began in both regions. During the first 15 days of each month, three GHSC-PSM teleoperators collect data on the stock available at each target health facility, with facility staff providing data from its up-to-date stock card. The project verifies data quality over the phone and by collecting sample stock cards for comparison both electronically and when making site visits. Call center operators have access to the Integrated Call Center tool that provides a list of all SDPs for which monthly inventory is required. When placing a call, the operators select the desired SDP and the call is routed through a gateway equipped with multiple SIM cards allowing the three operators to place simultaneous calls. The call center is also an auditable system since all calls are recorded. The Integrated Call Center tool has online inventory forms that the teleoperators fill out directly during their calls. The call center data allows for the calculation of the average monthly consumption for each product to estimate the quantities needed by each health facility. The call center is thus an available and accessible data source that can be used to triangulate with other data sources (such as patient records data or surveillance data on epidemic response) while waiting for the full operationalization of an electronic LMIS that will be interoperable with other data management systems.